Global

Functional

Catamold® – Creating solutions to manage the complexity for functional applications

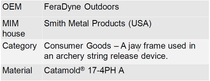

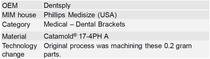

In today’s world metal injection molding has touched many systems to generate additional value such as design freedom and part integration. The functional segment in MIM is comprised of everyday products such as sporting goods, medical devices, industrial pumps, aero space compressors, and ultrasonic toothbrushes. Discover the amazing possibilities of powder injection molding for a variety of functional components: with Catamold® and BASF.

Catamold® enables the near-net-shape manufacturing of components even ones with complex geometries in metal – in large production quantities. As in the case of thermoplastics, many options are available right from the first processing step, injection molding: undercuts, cross holes, blind holes, grooves and threads as well as surface structures and lettering. Therefore Catamold® is the economic alternative to traditional technologies, e.g. investment casting.

Catamold® - Best in class feedstock for functional applications

Catamold® - Best in class feedstock for a variety of functional components

Catamold® - The right partner for your next project

BASF is a strong and well-known partner since decades for providing solutions to the global manufacturing network. We are the world-leader in commercial MIM Feedstock production and the inventor of fast and reliable catalytic debinding system. BASF is maintaining a global structure of sales, production & development to support our customers wherever they need us.

Catamold® is a strategic partnership for your business success and has a strong track record with many market leaders. Our product quality and consistency support customers with their success.

Catamold® is a sustainable technology with no metal scrap.

Industrialization of MIM is our profession and Innovation is our DNA.

If you want to learn more about our global business and functional applications, please contact us here.