Global

Product portfolio

Catamold® – A versatile portfolio for various industries

Material Selection

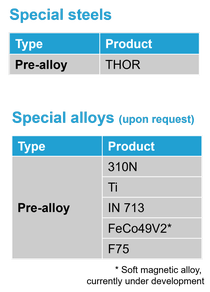

Broad portfolio for your specific applications and customized materials for special applications and needs*

* upon request

Catamold® – A versatile portfolio for various industries

Catamold® Material Selection

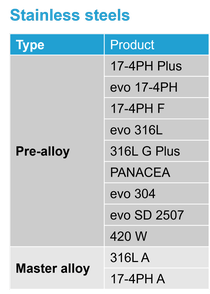

Catamold® 17-4PH: Components with high strength for applications in corrosive environments: Mechanical engineering, automotive industry, aviation, marine.

Catamold® 316L: Non-magnetizable parts with high corrosion resistance and toughness; polishability. Watches, decorative parts, medical equipment, parts for food and chemical industry.

Catamold® PANACEA: Non-magnetic parts with excellent corrosion resistance, medium hardness and good ductility used for watches, jewelry and in the medical- and food industry.

Catamold® 420W: Components with high hardness and wear resistance combined with good corrosion resistance against water and steam; e. g. tools, cutting blades, surgical instruments, nozzles, bearings.

Catamold® 304: Parts with good corrosion resistance and toughness. ICT applications like SIM card trays casings and structural parts. Mechanical and construction applications like tubes and casings, pumping systems, food and drug handling equipment, household goods.

Catamold® SD2507: Parts with good corrosion resistance and toughness. ICT applications like SIM card trays casings and structural parts. Mechanical and construction applications like tubes and casings, pumping systems, food and drug handling equipment, household goods.

Catamold® FN02: Versatile material with superior surface finish. Multiple applications, e. g. for automotive parts, mechanical engineering, etc. Also suited for magnetic applications, requiring high magnetic output.

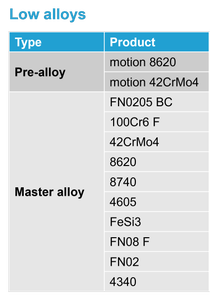

Catamold® FN0205BC: Ni Steel; heat treatable; Versatile material with superior surface finish.

Catamold® FN08F: Versatile material with superior surface finish. Multiple applications, e. g. for automotive parts, mechanical engineering etc.

Catamold® 8620/motion 8620: Low-alloy case hardening steel, can be case-hardened by both gas- or liquid-carburizing or carbonitriding; Components combining high surface hardness and core toughness.

Catamold® 8740: Components combining high surface hardness and core toughness for tools, automotive parts, mechanical engineering, etc..

Catamold® 42CrMo4/motion 42CrMo4: Components with high strength and toughness for tools, automotive parts, mechanical engineering, armament components. Surface treatment by blueing, phosphating, plating with chromium, nickel or zinc is possible.

Catamold® 100Cr6F: heat treatable low-alloy bearing steel; Components with high hardness and wear; hardness of ≥ 60 HRC can be reached.

Catamold® 4605: heat treatable Ni Steel; Versatile material with superior surface finish; Through heat treatment a wide range of mechanical properties can be covered.

Catamold® 4340: Components with high strength and toughness for tools, automotive parts, mechanical engineering, armament components. Surface treatment by blueing, phosphating, plating with chromium, nickel or zinc is possible.

Catamold® FeSi3: soft magnetic iron-silicon alloy; low magnetic loss and high electric resistance

Coercivity Hc = 73 A/m (@ r = 7.66 g/cm3)

Residual Induction Br = 1.154 T (@ r = 7.66 g/cm3)

Maximum Polarization Js (4 kA/m) = 1.573 T (@ r = 7.66 g/cm3)

Permeability μmax = 5215 (@ r = 7.66 g/cm3)